Product DevelopmentWhile

ongoing manufacturing, sales, and marketing produce your current

cash flow, your future profits are directly linked to the product

development Our approach to product development is based on the fact that no outside firm can duplicate the industry specific knowledge that has taken years to develop within your company. This realization is critical in allowing us to combine your industry specific knowledge with our engineering and product development knowledge and diverse background from many industries. You spend a little time to provide us the benefit of your knowledge, we provide our product development knowledge and the majority of the design time, and the result can be a more profitable product than either of us could have achieved on our own. Concurrent engineering is more than a popular buzzword at Product Design, Inc. When we say concept analysis we mean the whole product concept including not only the physical design of the product, but also how it will be produced and at what cost, what special tooling is required or profit enhancing, what level of service or user manuals are required, and how the product will fit into existing distribution channels. By following this "Work the Front End Hard" approach much of the uncertainty has been removed or reduced by the time serious money is committed to engineering the chosen concept into a complete product.

|

|

Engineering: Turning a Concept into a Profitable ProductIdeas

are a dime a dozen. It takes hard work to turn them into reality.

Hard core engineering supported with the right tools and the right

product development The ability of SolidWorks Simulation Ultimate to accurately solve component contacts quickly gives us the ability to analyze parts more accurately in the context of a realistic assembly. The speed of the Cosmos solvers gives us the ability to quickly perform analysis directly on Pro/engineer models without the need to spend excessive time building and simplifying FEA models.

|

|

|

Product

Design, Inc.

|

efforts that you are conducting today. This can cause a problem

in today's finely tuned manufacturing operations as the sharp focus

on manufacturing efficiency leaves not enough of the right kind

of resources available to successfully develop new products at the

rate the market requires.

efforts that you are conducting today. This can cause a problem

in today's finely tuned manufacturing operations as the sharp focus

on manufacturing efficiency leaves not enough of the right kind

of resources available to successfully develop new products at the

rate the market requires.

Concept

Selection: Matching Market Desires to Production Possibilities

Concept

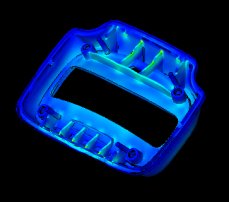

Selection: Matching Market Desires to Production Possibilities processes

are what it takes to make your product a reality. The picture at

right shows the result of a

processes

are what it takes to make your product a reality. The picture at

right shows the result of a

True

Concurrent

Engineering

is made possible by MBA level project management skills and

years of industry experience. These are combined with a strong

engineering background to insure that your project moves rapidly

towards successful completion.

True

Concurrent

Engineering

is made possible by MBA level project management skills and

years of industry experience. These are combined with a strong

engineering background to insure that your project moves rapidly

towards successful completion.