GALLERY

Personal

Ranger

for:

On-Course

Technologies

Chicago, Illinois

Product Design conceptualized and designed the freeform look, the polycarbonate case parts, the unique mounting used to attach the Personal Ranger to golf carts, and the simple plastic tool that the golf course official uses to remove the Personal Ranger from carts. The Personal Ranger is an example of a project in which the client provided their industry specific knowledge which was in electronics and software development while Product Design provided the plastic part design expertise. The Personal Ranger can be seen on many golf courses across the USA were it's introduction has created a cost effective way for a golf course to increase it's pace of play with minimal investment.

KR

Strikeforce

KR

Strikeforce

and Brunswick Zone

Bowling Ball Bags

for: KR Industries

Cicero, Illinois

The development of this product line is an excellent example of how we use the existing product, market, and distribution knowledge that exists in key people at client companies to develop new products. The key people at KR Strikeforce had developed a number of ideas about what features, impressions, and price points would constitute an improved high end rolling bowling ball bag. In addition they gave us an unbiased opinion of the pluses and minuses of competing bags that were on the market and how customers reacted to specific features of these products.

Based on this market knowledge Product Design developed a concept for a family of rolling bags that would wrap the functional benefits that KR was seeking to achieve into a design with a modern free flowing style that would stand out from the competition. The picture above shows the KR Strikeforce 3 Ball Special Edition version of this product line. Variations on this design include the KR Strikeforce 2 Ball Special Edition, the Brunswick Zone 2 Ball, and the Brunswick Zone 3 Ball. The results of this project can be seen in bowling alley pro shops across the USA were this product line has firmly captured the high end segment of the market.

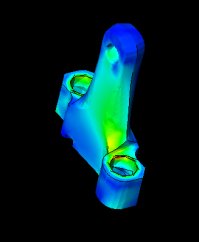

Stress Analysis of Engine Lift Bracket

for:

Cooper

Energy Services

Springfield, Ohio

Product Design developed a program to refine, test, and document the design safety of the lift brackets that were being developed for a 56,000 lbs. 16 cylinder natural gas fired engine.

Our background as a former defense contractor and as an expert witness in legal proceedings allowed us to develop a program that would confirm design decisions, refine the design to withstand potential off design conditions and usages, and document the resulting design in such a way so that it would stand up over time. Our in house engineering skills and FEA capabilities were used to validate the work of all outside consultants.

Product

Design, Inc.

5100 Main St. LL102

Downers Grove, Illinois 60515

Phone: 630.663.1642

Fax: 630.663.4552

5100 Main St. LL102

Downers Grove, Illinois 60515

Phone: 630.663.1642

Fax: 630.663.4552

Home | Product Development | Concepts | Engineering | Moldflow