Plastic Part Design

The

design of products using plastic parts is the primary product development

service offered by Product Design. Our other services in the areas of

FEA stress analysis and injection mold design and sourcing give us added

capabilities that enhance our core plastic part design skills. Our location

in the suburban Chicago, Illinois area places us in the heart of one of

the highest concentrations of plastic injection molders in the world.

This location gives us access to many molders and exposes us to new designs,

techniques, and problems. The result is a well developed and constantly

improving set of plastic part design skills.

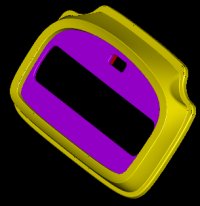

Plastic Part Styling

Injection molded plastic parts can be designed to provide good looking products that consumers want to buy at no additional cost over lacklustre "follow the herd" products that have no sales appeal. To do this you need the right product concept, the right people, and the right tools. The good looking new products on the market today are almost always designed with the use of an industrial strength solid modeling CAD system with good surface modeling capabilities such as Creo. Our experience in Creo Surface Molding surface modeling gives us the skills and tools required to create parts with sales appeal that are designed for economical injection molding.

The right tools alone are not enough to create good looking parts. A designer with a sense of style who is working with an strong look concept is required to deliver a product look that will sell. Our experience in creating appealing plastic parts in Creo can help you turn an idea for a good product into the physical reality of a well designed plastic product.

Design for Production

More than any other material, parts made from plastic must be "designed for production". Anyone can design a plastic part to some degree, but to do it well a knowledge of the injection molding process and how injection molds function is required in addition to "regular" design skills . Our previous service of providing injection molds of our design to our clients gives us an in depth knowledge of injection molds and injection molding problems. This knowledge combined with our Creo and FEA stress analysis capabilities gives us a very strong background from which to design plastic parts.

Plastic Part Stress Analysis

It is no news that plastics have very different structural characteristics than metals. Yet even a common term like stress has a very different implication for a plastic part than it would have for a metal part. The real question is how do these differing material characteristics effect the design process?

Plastics are thought of as a low cost material but in reality they are fairly expensive when viewed from a unit volume or load bearing basis. Plastic components end up being low cost due to the high speed of the injection molding process. With this in mind 100% plastic products are not always the best way to get the most cost effective product. Plastics in general can handle intermittent loads well but will deform permanently under even low levels of long term applied loads. Frequently no reasonable amount of plastic can be added to a design to overcome this characteristic so instead a few load bearing metal components added to a primarily plastic design will result in a superior product.

An

example of this approach is our design of the KR

Industries and Brunswick Zone 3 Ball Rolling

Bowling Ball Bag. This is primarily a plastic product design, however

two aluminum tubes were used to get around the structural limitations

of the impact  modified

polypropylene material that made up the 3.2 lbs. injection molded main

body. These tubes doubled as the guide tubes for the retractable handle

and as stiffeners to resist the weight of 3 bowling balls.

modified

polypropylene material that made up the 3.2 lbs. injection molded main

body. These tubes doubled as the guide tubes for the retractable handle

and as stiffeners to resist the weight of 3 bowling balls.

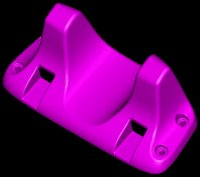

At right is a view from the bottom of the end stand from the latest KR Industries and Brunswick Zone 3 Ball Rolling Bowling Ball Bag. This part transmits the load of the bowling balls into the floor when the bag is at rest. The design of this part was balanced to withstand static loads during long periods of storage without permanent deformation and also large impact loads during rough handling when loaded with 48 lbs. of bowling balls. Our in house FEA capabilities allowed us to test design approaches to this problem in software and then go directly to tooling without spending large amounts of time prototyping and testing. This part has yet to see any field failures even though it uses less plastic than the failure prone part that it replaced in the same application.

Notice that the above design depends on the interaction of the components in the assembly. Any analysis of individual plastic parts would be meaningless in this case as it would neglect the stiffening effect of the large aluminum tubes. This illustrates the fact that in real life many parts are loaded as part of an assembly. For this reason any FEA analysis of plastic designs must handle not only the non linear material properties of the plastic material but handle the assembly contact conditions, constraints and loadings accurately. Our in house non linear FEA stress analysis capabilities using SolidWorks Simulation Ultimate allows us to provide meaningful stress analysis of plastic products. This capability allows us to confidently develop cost effective plastic parts that work.

Product

Design, Inc.

5100 Main St. LL102

Downers Grove, Illinois 60515

Phone: 630.663.1642

Fax: 630.663.4552

Home | Product Development | Concepts | Engineering | Moldflow