FEA

Stress Analysis

Stress analysis services using Finite Element Analysis or FEA are provided from our suburban Chicago, Illinois location. Our FEA services are combined with our experience in plastic part design and injection mold design to deliver our customers products that look good, are structurally sound, and will mold economically. For client product development projects we use SolidWorks Simulation Ultimate FEA software to perform linear static and non linear static analysis on plastic parts and assemblies. In the area of thermal analysis, the recently added capability of SolidWorks to handle material enthalpy as the plastic cools in the mold is giving us a much more accurate estimate of the actual cooling loads we will see. This allows us to further improve the design of our economical plastic injection molds so that they run as fast as possible.

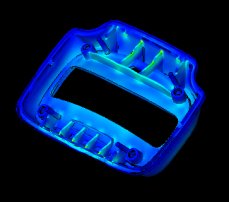

Shown at above is a plot of the Von Mises stresses on a plastic cover during an investigation into the most effective rib locations for this part. Notice that we were able to mesh and analyze this part directly from a Pro/engineer solid model without the need to simplify the part by suppressing draft and small finish rounds.

SolidWorks SIMULATION ULTIMATE-FEA

WWe

use SolidWorks Simulation Ultimate finite element analysis packages

by Desault SystemsStructural

Research and Analysis Corp.

These software packages provide us with basic linear static stress, frequency,

buckling, and thermal analysis capabilities in  addition

to non linear capabilities that allow us to handle plastics, assemblies,

and other situations that are beyond the capabilities of basic linear

FEA programs. The Cosmos FEA packages have traditionally had very fast

solvers so we can learn more about our design alternatives faster.

addition

to non linear capabilities that allow us to handle plastics, assemblies,

and other situations that are beyond the capabilities of basic linear

FEA programs. The Cosmos FEA packages have traditionally had very fast

solvers so we can learn more about our design alternatives faster.

Most

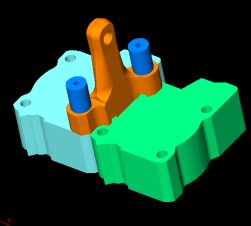

FEA work done at Product Design is done in the context of a simple assembly.

This allows more accurate input of loads and constraints due to the ability

of Cosmos to accurately handle the component contacts and to solve the

contact problems quickly. The assembly at right is from our analysis of

a set of lift brackets used to lift a 56,000 lb. 16 cylinder engine. This

simple assembly is used to constrain and load the gold colored lift bracket

in question.

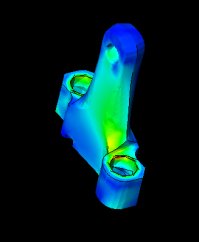

After the analysis is run the other parts are blanked as shown below to show the Von Mises stress levels on the part

of primary interest.

blanked as shown below to show the Von Mises stress levels on the part

of primary interest.

Basic FEA Service

Product Design provides a basic FEA service for manufacturers and design houses looking for a quick straightforward analysis of their design by experienced design engineers. Our decision to offer this service is a result of a scarcity of sources that can provide basic FEA stress analysis without turning the job into a major project.

- Work is performed by experienced engineers, not PhD level analysts. Our engineers can look at your drawings or solid models and figure out the correct constraints and loadings. For jobs that are not pushing the cutting edge of FEA theory getting the loading and constraints correct is the key to analysis results that reflect real world conditions.

- We charge on a time and material basis and do not spend time and/or money generating fancy proposals. We can usually tell you a price range for the work you require by looking at the part or assembly.

- We analyze most parts as part of an assembly. In real life most parts are loaded as part of an assembly. Many of the low cost FEA programs that plug into CAD programs have limited assembly functionality or can only analyze individual parts.

- You get a basic automatically generated report that actually documents what was done. We tell you what we did and why, what the loads and constraints are in understandable language, what the results are, and provide a brief recommendation based on our experience as degreed mechanical engineers.

Feel free to call to discuss how our basic FEA service can give your design engineers the timely feedback they need to keep their projects on schedule without creating another drain on their already scarce time resources.

Product

Design, Inc.

5100 Main St. LL102

Downers Grove, Illinois 60515

Phone: 630.663.1642

Fax: 630.663.4552

Home | Product Development | Concepts | Engineering | Moldflow