Concept DevelopmentBefore we attempt to start product concept development of any type we first get educated: By you, your customers, your current suppliers, your competitors, and any other place that we can learn about your industry. At Product Design concepts are more than just pie in the sky ideas. We use formalized techniques to turn the education, information, and ideas that we collect into concrete product concepts. Concepts are supported early on with our software tools to get a strong feel for a concept's reaction to a number of potential situations. Extreme value testing is conducted to help determine which concepts are most tolerant to design, production, and user environment variables. Our concept generation phase also collects the type of information that make detailed design and engineering easier, faster, and less uncertain. Trends can make or break a product. Only the strongest and rarest new product concepts can swim against a strong trend, conversely a marginal or "me too" product may be able to swim along with a favorable trend for a long and profitable life cycle. Knowing this, we spend time attempting to learn which trends in your industry are rising so that we can attempt to "Ride the Wave" of curent trends.

|

|

Comparing Concept Appearance

While we use clay models and foam mock ups, early concepts can be evaluated more quickly in software that has the ability to change the shapes, colors, and textures that a part is "wearing". Here SolidWorks is shown with a shape in different colors. |

|

Systematic

Concept Selection One of our tools for evaluating competing product concepts is the Pugh Concept Selection Matrix. This method promotes evaluation based on actual product characteristics instead of gut feeling or the opinion of the strongest person in the group.

|

|

|

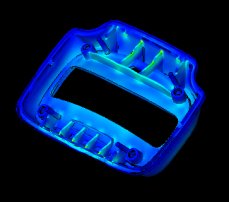

Taking Advantage of Rapid Prototyping

|

|

Product

Design, Inc.

|

The

ability of Pro/ENGINEER software to generate high quality SLA files

gives us faster turnaround and lower costs when taking advantage

of rapid prototype resources during concept evaluations

The

ability of Pro/ENGINEER software to generate high quality SLA files

gives us faster turnaround and lower costs when taking advantage

of rapid prototype resources during concept evaluations