Moldflow

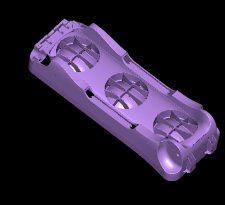

Product Design, Inc. uses Moldflow products to improve the moldability of our plastic part designs. Most molding problems are a byproduct of the plastic part design itself. Since molding problems do not present themselves until after the mold is built, fixing these problems is usually costly and always causes considerable delay. By using a tool like Moldflow during the part design phase we can greatly reduce the chances of molding problems later in the project. Moldflow cannot turn a bad injection mold into a good injection mold, so it must be used during the part design phase for maximum benefit.

.

Moldflow

as a design check

The common usage of moldflow is as a design checker that is used as a part is nearing completion. As plastic part designs get more complex it is more difficult to predict the performance of the part as it is being molded or even if the part can be molded. Moldflow can improve your confidence in mold fill, sink marks, warp and knit lines prediction and therefore reduce the risk of molding problems that are a byproduct of the part design.

Moldflow as a conceptual tool

Our favorite use of Moldflow is as a concept development tool. All good designs are based on one or more strong concepts. Just as a strong appearance or structural concept can be the key to turning a good idea into a functional product, a good plastic flow concept can turn an unmoldable problem part design into a cost effective, easy to mold part.

Product

Design, Inc.

5100 Main St. LL102

Downers Grove, Illinois 60515

Phone: 630.663.1642

Fax: 630.663.4552

Home | Product Development | Concepts | Engineering | Moldflow